READYMADE GARMENTS

Crafting the dream of glorious inherited skill to be the pillar of develop nation

The history of the industry in Bengal is very old. Century to century, Bangladeshi textile industry is very renowned for dressing the world. From the glorious golden past of Dhakaiya Muslin to today’s Ready Made Garments industry, Bangladesh is developing the sector with skills, technology and sustainable commercial strategy. In 1972, the World Bank estimated Bangladesh’s gross domestic product (GDP) at US$6.29 billion. It was 1978 when Bangladesh had only nine “export-oriented” garment manufacturing units. That same year the first direct export of garments, 10,000 shirts to a Parisian firm, was shipped from a Bangladeshi firm. And now it grew to $353 billion by 2021, of which $46 billion was generated by exports, 82% of which were readymade garments. Minimum Wages increased by 381% since 2010, from BDT 1662.50 to BDT 8000 per month. Job creation and income growth have helped reduce poverty, improve human development, and empower women who make up two-thirds of the sector’s 3 million workers. over the past decade as leading companies, under the umbrella of Bangladesh Garment Manufacturers and Exporters Association (BGMEA), modernized the industry and significantly improved the safety and the wellbeing of workers. The industry aims to increase its share of the global RMG market by diversifying its products and markets and adopting global standards in ethical practices and sustainability.

- Minimum monthly wage of a unskilled worker is BDT 8000, average wage per worker is BDT 9500, and average take home wage is BDT 12,500 including 2 hours overtime / day. So average monthly take home is around US$ 148.

- Central Fund for the welfare of the workers, where RMG contributes $12 million per year (0.03% on the export payment received).

- Safety Committee and Elected Participation Committee are mandatory by Law in every factory.

- Home to the world’s highest number of green factories.

2nd LARGEST GARMENTS EXPORTER IN THE WORLD

2015-16

$28.09b

2016-17

$28.15b

2017-18

$30.61b

2018-19

$34.13b

2019-20

$27.95b

2020-21

$31.45b

EMPOWERING WOMEN & PRESERVING DIGNITY

- The 3 million female workers are mostly within the age group of 18-30 years.

- Women have become self-aware, independent and free within the society.

- Early marriage and early motherhood has dropped.

- Primary education enrolment has increased.

- Child and women mortality rate has dropped.

- Improved maternal and child health and nutrition.

- Poverty declined to 20.5% from 40% in 2009.

- According to World Bank data, the infant mortality rate decreased from 92 in 1991 to 26 per 1000 live births in 2019 while maternal mortality rate came down to 172 in 2017 from 472 per 100,000 live births in 1991.

- Female literacy rate has increased from 56% in 1990 to 72.30% 2019.

- It is observed that between this period the apparel industry grew considerably creating jobs opportunities for more women in the country.

A study conducted by Rachel Heath of the University of Washington and Ahmed Mushfiq Mobarak of Yale University’s School of Management suggests that ‘the garment industry’s contribution to female education. According to the study, 27 percent more young girls were going to school than before the emergence of garment industry in Bangladesh’.

INDUSTRY INNOVATION AND EFFICIENCY

Garment factories in Bangladesh usually tend to get the design from the brands and buyers and replicate due to deficiency in product development capacity. Having own product development capacity helps better in terms of negotiation and profitability. Lead time of production is also one of the major impediments for the industry. Modern software for fabric cutting optimization, 3D sampling and pattern making are being used in the global fashion industry to make the processes faster and easier. To keep pace with the changing demands, Bangladesh RMG industry also feels the need to embrace innovation in the production system. Thus, BGMEA has taken an initiative to establish a centre for productivity, innovation, and OSH for garment factories to enhance competitiveness of the RMG industry of Bangladesh.

It’s a matter of great achievement for us that, we are regularly trying to produce diversified products. Our product categories are increasing day by day. Our product items that are exported into the foreign market are Shirts-60%, Jackets-11%, Knit items-10%, Trousers-7%, and Others-11.50%. Beside all of these we are developing some new categories to enhance the supply and capturing some bigger market.

WORKERS HEALTH

BGMEA has taken massive number of steps to protect the workers and the industry from the ongoing pandemic which has brought a catastrophe to our life. Starting from factory health and safety protocols, telemedicine, collaboration with Maya, CommonHealth, BSMMU; Online platform Inspectorio, dedicated PCR labs for testing workers, isolation center, factory audits and many more. It has helped us to keep the infection below 0.03% and we may tell that we have successfully moved out from the direst situation started in March-April. However, the chance of a second wave or second strive of infection cannot be ignored and BGMEA is taking precautions for combating the worst-case scenario accordingly.

SDG 3 Business relevance

Business actions that relate to SDG 3 include encouragement of a healthy lifestyle; supporting access to healthcare; medical coverage offered to employees and their families; ensuring that company policies and practices respect reproductive rights; supporting the needs of mothers and children; supporting access to mental health care; promoting safe and healthy surroundings around factory facilities; providing training or information on road safety to employees, etc.

Type of data collected

Mostly quantitative data was collected relating to parental leave, retention rate after enjoying parental leave, other health-related benefits that employees and workers are receiving.

Results

Factories are consistently investing in and improving the retention of women employees after maternity. Most of the factories provide health insurance11 complemented by subsidized access to health care products, such as sanitary napkins12. The average retention rate of reintegration at work after maternity leave increased by 3% in the financial year 2018-2019, and by 7% in the financial year 2019-2020 despite the challenges faced by the industry during this fiscal year [Figure 3]. 17% factories have paternity leave policy

112

101

96

Average Entitled for Maternity Leave

108

100

94

Average Leave Taken

98

88

83

Average come back into work after taking

maternity leave

74

62

55

Average come back into work and stay

12 months after taking maternity leave

FY 2017-18

FY 2018-19

FY 2019-20

GREEN GROWTH

145 LEED Green garments factories certified by the U.S. Green Building Council (USGBC)

40 out of the world’s top 100 garment factories are in Bangladesh

500 more factories are in the process of getting LEED certification

BGMEA Pledges to the Green Button which is a global seal of excellence in sustainability by the Government of Germany.

For its outstanding contribution to promote green factory, BGMEA awarded with “2021: USGBC Leadership award”

Green Factories

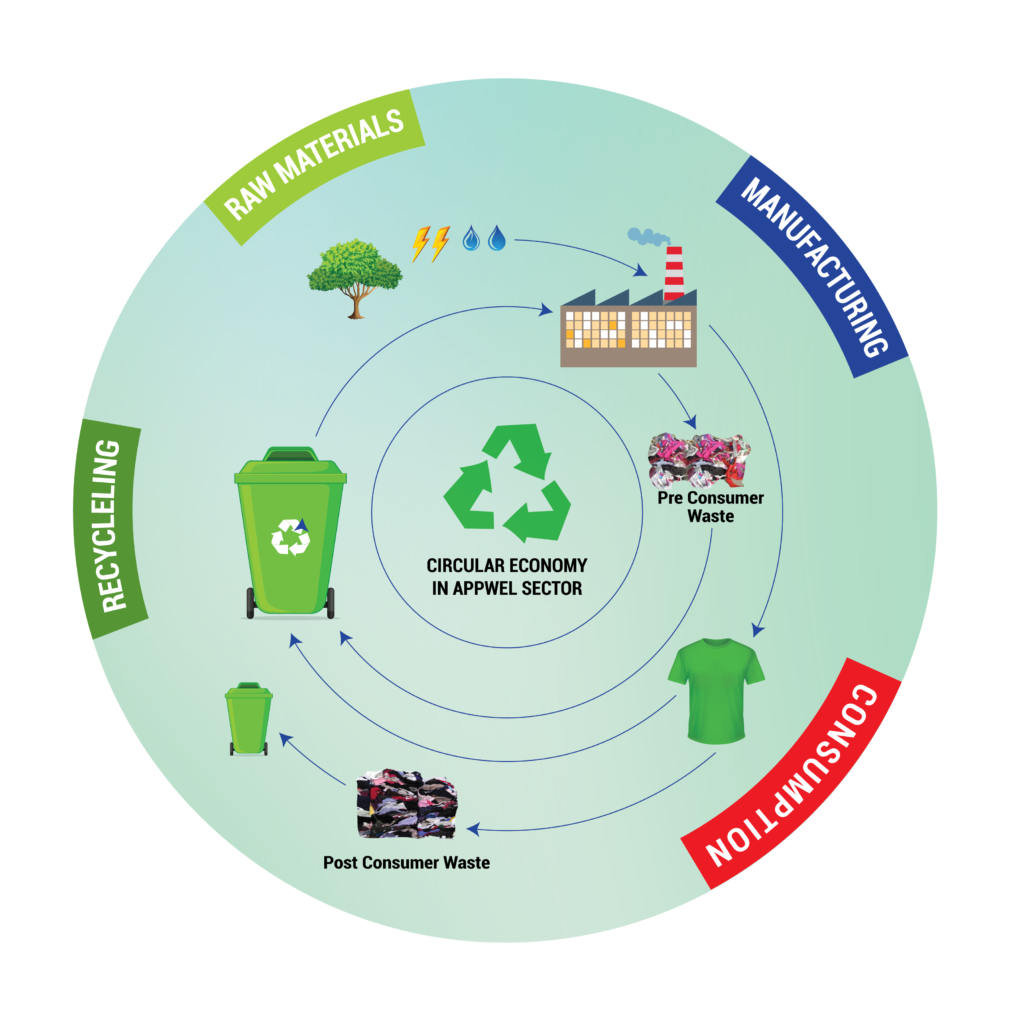

CIRCULAR ECONOMY – CFP, SDG-12, MFC

- P4G funded Circular Fashion Partnership initiative aiming to achieve a long-term, scalable transition to a circular fashion system that produces new, low carbon footprint and responsibly-made products

- Partnership between Global Fashion Agenda (GFA), BGMEA and Reverse Resources (RR)

- 19 brands, 17 recyclers and 85 manufacturers on-board

- Per factory generated average waste found to be around 7322 kg/month

- BGMEA’s continuous stride towards achieving SDG 12 on ‘Responsible consumption and production’ through circular economy

- BGMEA contributed to Ellen MacArthur Foundation’s ‘Vision of a circular economy for fashion’ report